We hear this all the time, a friend installed a set of wheel spacer and while cruising on the highway, the wheel let go. Terrible thing! We all blame it on the wheel spacer but is it really the wheel spacer? Let’s take a moment to talk about what keeps the wheel on.

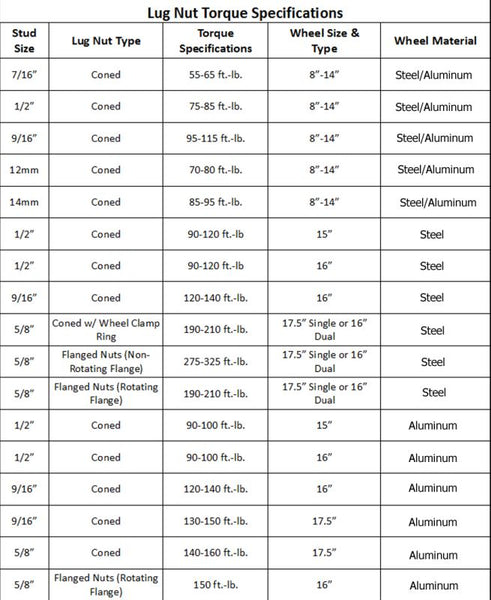

The wheel studs on a car acts as a clamping force that holds the wheel to the hub. When we go to tighten the lug nuts, the wheel studs act like a spring providing elastic force to hold the wheel on properly. The specific torque spec for the vehicle tightens the studs at 90% of its elastic limit yielding the highest possible force to hold the wheel to the hub.

This is very important because of the coefficient of friction involved in holding the wheel on the hub. Generally, the more clamping force to hold the wheel onto the hub, more force it requires for the wheel to slip on the hub. That being said, there cannot be any bending load on the stud.

Why do we need to consider the coefficient of friction? Because this is the ratio of normal force at the contact of the two surfaces to the lateral force required to slip the bodies relative to one another. Performance street tires have a coefficient of friction of 0.9. What does this mean? This means at 100lb of vertical force, there exist 90lb of corning force before it slides.

As the car moves, the stress on the wheel studs does not change unless one of the vertical component of any external force applied to the wheel exceed the clamping force and causing the wheel in place to slip on the hub. The wheel studs then is loaded and may bend, sheer or in some cases break.

If, there isn’t sufficient clamping force or there is too much clamping force between the wheel and the hub, there will be flexing and the tension load on the wheel studs then drop to zero. With no tension load on the stud, the clamped joint is no longer tight. This results in a bending load on the wheel studs and thus the wheel let go. This is how wheels fall off on cars.

By Inserting a wheel spacer between the hub and wheel will changes nothing to the physics of holding the wheel on. By utilizing longer wheel studs for wider wheel spacers will have no negative effects to the wheel and hub. The key is to have quality wheels, hub and spacer that are rigid and stuff. What causes failure is flexing and loss of clamping force. A properly installed wheel spacers are perfectly safe. Always check the torque required for your specific car when installing wheel spacers.